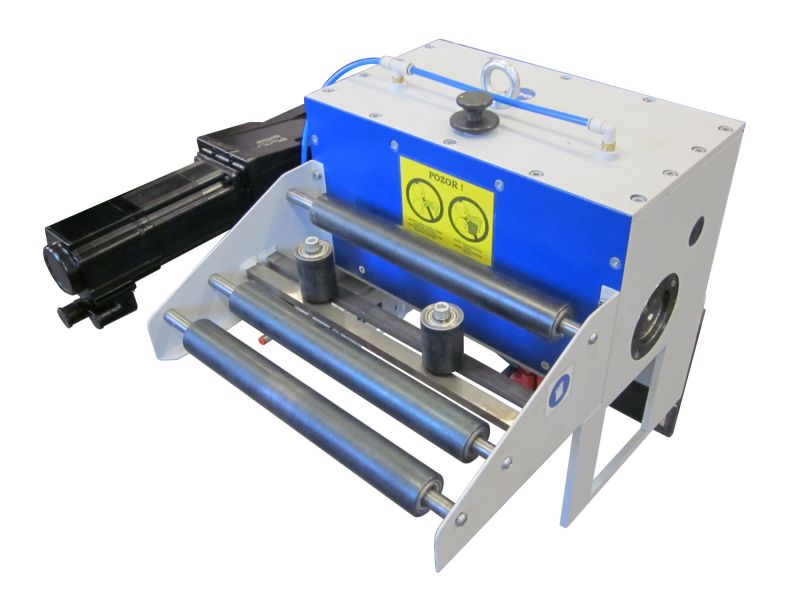

Roll feeder is additional equipment used in press manufacturing. It feeds accurate length of metal belt into a working area of the forming press. The roll feeder enlarges the usability of a forming machine and maximalizes its productivity simultaneously.

It feeds accurate length of metal belt into a working area of the forming press. The roll feeder enlarges the usability of a forming machine and maximalizes its productivity simultaneously.

Mechanical realization

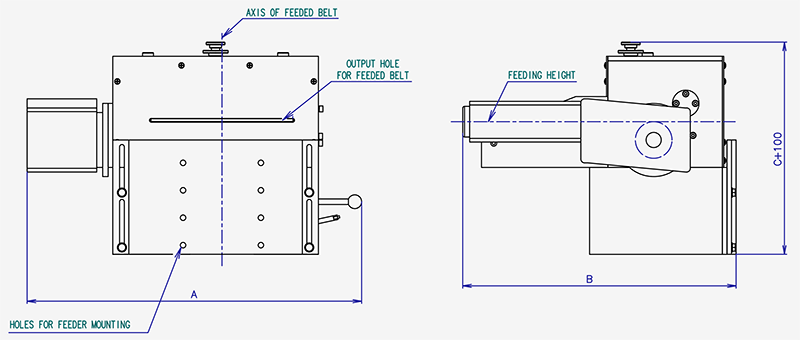

A chassis of the feeder is welded from metal sheets, which ensures great stiffness of the whole machine. Inside the chassis, there are two hardened rolls, which are used for pulling a material. On the side of the bottom roll is placed gear with servomotor. The upper roll, mounted in tiltable beam, is propelled by gear wheels. Pressure of the upper roll is ensured by two single-acting pneumatic cylinders, which are placed inside the chassis. Feed height can be adjusted by hydraulic jack or ball screw.

As standard, we attach input rolls for shoring of metal belt before it enters the feeder. Side belt alignment is done by two vertical hardened rolls, whose position is adjustable according to belt width.

Feeder control

Main rotating movement is made by servomotor with gear manufactured by LENZE. PLC motion controller controls this motor. Feed parameters are displayed and can be set via touch display located on the front panel.

List of basic parameters, which are possible to set via display:

| Parameter | Possible range | Unit |

|---|---|---|

| Feed length | 0,10 – 9999,99 | mm |

| Feed velocity | 1 – 100 | % |

| Number of feeds | 1 – 999 999 | ks |

| Number of feeds(2nd counter) | 1 – 999 999 | ks |

| Press stroke launching modes | Single stroke, Continuous | – |

| Starting and ending feed angle | 0 – 359, 0 – 359 | ° |

| Starting and ending freeing angle | 0 – 359, 0 – 359 | ° |

| Digital cam (relay contact) | 0 – 359, 0 – 359 | ° |

| Feed accuracy testing | 0 – 359 | ° |

Additional equipment

In the case of customer interest, we offer following additional equipment to the roll feeder:

- External feedback measurement of feed length (eliminates inaccuracy caused by slip of feed rolls)

- Additional checks according to customer needs

- Additional electronic cams for co-operating machines in automation line

- Check for belt ripple between the feeder and a machine tool (useful when narrow or thin metal belt is feeded)

- Portable control panel for comfortable belt loading in forming press working area

- Multiple feeding of different lengths in a row, “receipts” for manufactured parts

We also offer non-standard equipment (additional sensors, special-shape forming rolls, etc.). Our products are tailor-made solutions, effectively integrated into production and forming process.

Feel free to contact us for getting additional information.